Wallis Drilling is a leading drilling services provider, with extensive experience in Australia and selected international markets.

Our company is renowned for its innovative custom-designed drill rigs, experienced professional team and commitment to quality and safety.

Click here to speak to a member of our Wallis team

When people think of a company they think of hard assets. Little thought is given to the real asset of a company, the people. Wallis Drilling has a great people asset. They are the drivers of all that we do. Our technical base that creates the hardware assets and the people who put them to work are the company. Wallis Drilling has always been creative thanks to the drive and resourcefulness of people, working under harsh conditions wanting a better way of doing the work and being more productive.

Jamie Wallis, Co-Founder Wallis Drilling

Extensive Experience

At Wallis we have been building our technical knowledge and hands-on expertise since 1965. Our comprehensive services for exploration and mining projects include: air core; reverse circulation; mud rotary; diamond core; grade control; and blast hole drilling.

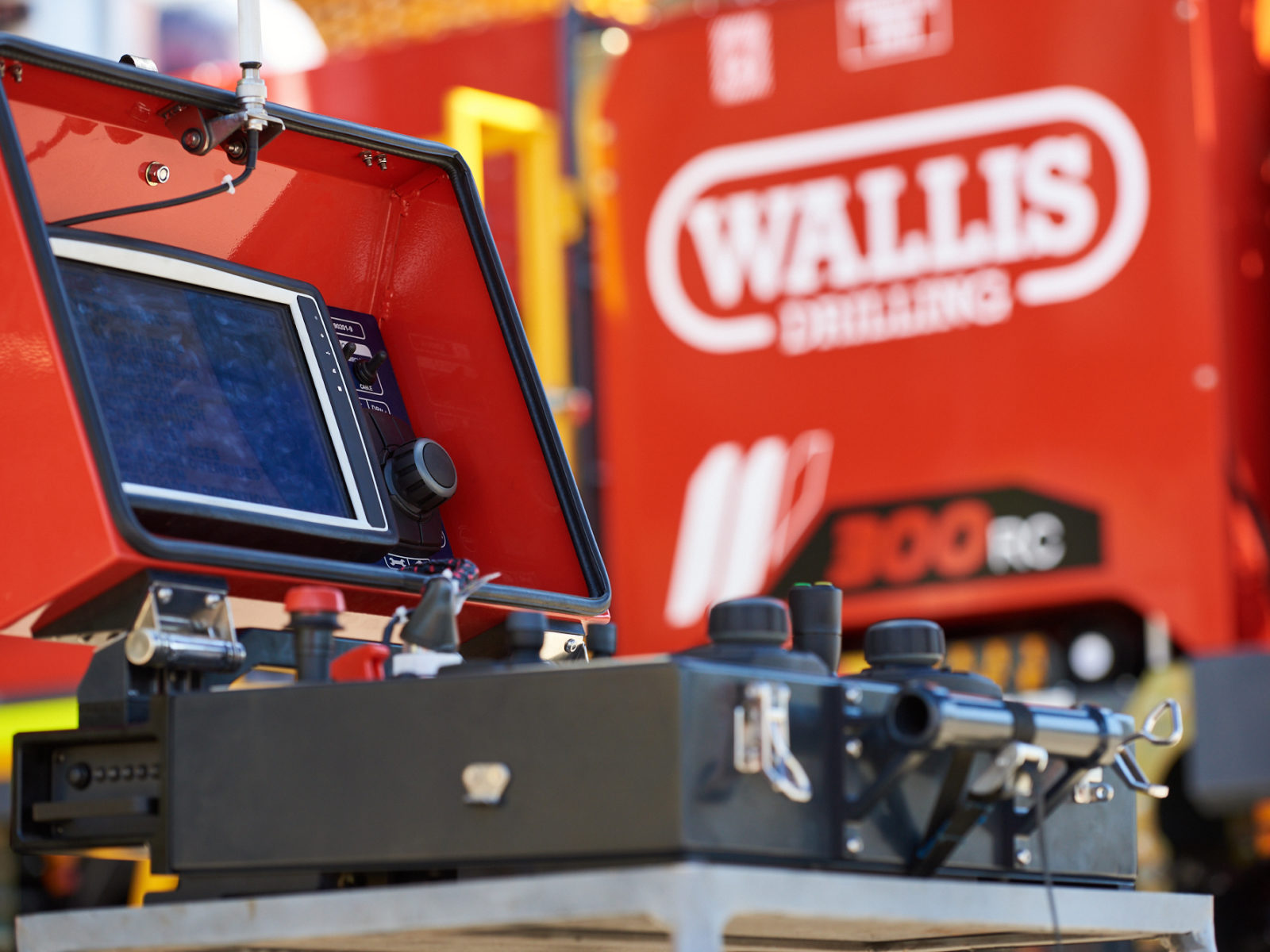

Innovative Custom-Designed Drill Rigs

In 1974, our founders Marty and Jamie Wallis invented the Wallis Aircore drilling system, which revolutionised drilling globally.

Their passion for solving clients’ challenges remains central to our company’s culture today and we continue to lead the industry developing innovative drill rigs that meet and exceed the expectations of our major resource customers.

Commitment to Quality & Safety

We are committed to the highest standards of quality and safety for our clients and employees. The following quality assurance accreditations have been maintained since 2003:

- ISO 9001:2015 Quality Management System;

- ISO 14001:2015 Environmental Management System;

- ISO 45001:2018 Occupational Health and Safety Management System; and

- ISO 55001:2014 Asset Management System (achieved in 2019)